18 August 2025

Hoodman Corporation has a rich 40-year history of creating innovative products designed to enhance outdoor performance in various professional fields.

For four decades, Hoodman has been at the forefront of developing practical, high-quality products that empower professionals to perform at their best, especially when operating "in the field." This dedication to utility and durability has seen the company evolve significantly, adapting to new technologies and customer needs while staying true to its core philosophy.

Today, the drone industry widely recognizes Hoodman's distinctive big orange drone landing pads. For the past ten years, a significant part of Hoodman's mission has involved educating the rapidly growing drone sector about the tangible benefits these landing pads offer. Specifically, they help drone pilots achieve more flight hours by minimizing wear and tear, thereby reducing the need for frequent repairs. This focus on enhancing operational efficiency is a hallmark of Hoodman's approach.

Hoodman Hoods and the NFL

However, Hoodman's journey didn't begin with drones. The company had already established a strong reputation for creating useful tools for image-makers for 30 years prior to the advent of unmanned aerial vehicles. For those who have followed the National Football League (NFL) since 1996, Hoodman's impact has been directly visible. Hoodman Hoods have played a crucial role in allowing NFL referees to view instant replays glare-free, directly on the field. This innovation all started with a proactive call made in 1995 to the head NFL referee. At that time, NFL replays were reviewed from the press box, creating a sense of detachment, almost like decisions were being handed down from on high, with minimal crowd interaction. During that pivotal call, the founder of Hoodman proposed bringing the replay monitors directly onto the field, enabling referees to make immediate calls amidst the energy of roaring crowds. He assured the referee that Hoodman Corporation could make this vision a reality.

Hoodman had already been perfecting glare-fighting hoods for the television and motion picture industries since 1986, catering to professionals who needed to view monitors clearly in bright outdoor conditions. Following the call, the head referee expressed his interest and received a Hoodman Hood Brochure via traditional mail. The following year, the same referee contacted Hoodman, announcing that the 1996 preseason games would trial on-field replays and that television networks would be reaching out for hood purchases. Orders were placed, and given the existing familiarity of the TV crews with Hoodman's products, the transition was seamless. However, at the conclusion of the preseason games, team owners voted on whether to permanently adopt on-field replays. To Hoodman's initial disappointment, on-field replays were voted down. Fortunately, this setback was short-lived, as the NFL embraced on-field replay viewing just one year later. The Hood designs continued to evolve over the years, and the NFL business proved to be a highly enjoyable and impactful venture. Today, Hoodman hoods are still utilized in college football replays, operating under the brand name DV Sport.

Returning to the world of drones and Hoodman's commitment to creating products that improve field performance, the company had already built a solid reputation for equipping TV, motion picture crews, and photographers on location with essential tools. During an exhibition at the National Association of Broadcasters trade show in 2015, a significant trend emerged: the first ten customers to enter the Hoodman booth specifically requested hoods for iPad minis. Upon inquiring about their use, each customer revealed they were flying drones. Within six weeks, Hoodman had developed and launched a line of glare-fighting aviator hoods with touchscreen access, compatible with the entire iPad range. Just three months later,Hoodman made its debut at its first drone show, selling out of all the aviator hoods brought to the event. Through interactions with the enthusiastic drone pilot community, it became clear that drone landing pads with weighted perimeters would be immensely beneficial. The key challenge was devising a method to secure the pad against wind and drone thrust without the need for stakes. Hoodman determined that using steel cable rope would provide an ideal solution, offering both superior stability and easy packability.

The first landing pad produced was an 8-foot diameter model, sold to an Alta flyer in Hollywood. The pilot was reportedly amazed by the pad's unwavering stability, confirming its resistance to movement. The next size developed was a 5-foot pad, designed for Inspire-sized drones. Subsequently, 3-foot and 2-foot pads were created as drones became smaller. The product line culminated with a 21-inch pad, engineered to conform to and hug the ground without requiring any cables around its perimeter. This more affordably priced pad proved ideal for sale to small drone flyers on platforms like Amazon. Hoodman has also produced custom pads as large as 12 feet in diameter for specialized projects. Considering the area of a circle formula (Area = πr²), a 12-foot diameter pad covers no less than 113 square feet, while an 8-foot pad covers 50 square feet. The addition of just four feet to the diameter more than doubles the landing surface area, illustrating the significant impact of adding to pad diameters.

Hoodman and Army Drone Reconnaissance

Hoodman's impact extends to saving lives, particularly for US Army Drone reconnaissance pilots. The company had already mastered the challenge of daytime glare relief, but the Army required a solution to prevent pilots flying night operations from having their faces illuminated by their controller LCD screens. Maintaining stealth was paramount for survival during these missions, as no one wants to become a visible sniper target in the dark. Hoodman developed a specialized solution for military pilots, addressing this critical need. This 7-year project with the US Army proved to be both financially rewarding and deeply patriotic, contributing to the safety and survival of troops.

Beyond these specialized applications, Hoodman also ventured into producing top-tier memory cards for digital cameras, serving the photo dealer channel for a significant 15-year period. This represented a considerable leap from low-tech hoods to high-speed memory cards. Hoodman partnered with a reputable production facility in Silicon Valley, enabling them to manufacture memory cards that outperformed competitors in terms of speed and longevity. The company's consistent business model has always revolved around creating products that deliver exceptional performance and possess a long lifespan for their customers. Demanding image makers required faster memory cards to capture fleeting moments of action, and they also needed memory cards that would not fail after just a year of use. The type of NAND flash memory utilized in Hoodman's cards was robust enough for deployment in devices on missions to Mars, underscoring the company's commitment to delivering high-value products.

Hoodman at Trade Shows

Throughout its history, Hoodman has also embraced the creative process, finding joy in crafting innovative items that enhance people's field performance. The company maintains a grounded perspective, reminding itself that while they aren't manufacturing critical medical devices like heart valves, the pursuit of creating excellent products should be an enjoyable endeavor. Hoodman's branding is also a significant aspect of its identity, as evidenced by its distinctive trade show booths.

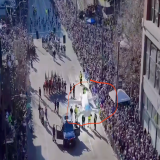

Photo above is from 2009 in the debut of the HoodDome booth space at the PhotoPlus Expo at the Javits Center in NYC.

Hoodman remains committed to customer-driven innovation, so if you have a product idea for the drone industry, don't hesitate to reach out.