28 January 2023

By Mike Walters, Vice President, Teledyne FLIR

Integration of new sensing types within UAVs is quickly making drones indispensable for industrial and commercial inspection applications. Going further, the ability to fly with multiple sensor types together, from visible imaging to thermal, is also improving the utility and productivity of operators ranging from UAV pilots to maintenance personnel acting on the inspection data.

However, just as critical to capturing the data in flight is interpreting the data post-mission. Whether the mission is to pinpoint water damage on a large warehouse roof or to assess solar panels within a solar farm, the ability to take that data and turn it into action is where UAV inspection drives true value.

UAV Inspections Start with the Airframe

Pilots need access to domestic drone makers making airframes and sensors that are secure by design. Since its introduction this fall, the Teledyne FLIR SIRAS drone has impressed the industry with its mix of features that enable it to perform a variety of commercial and industrial applications quickly, easily, and securely.

The SIRAS does not connect to the internet, local Wi-Fi, or cellular networks. This prevents pathways that too easily enable third parties and hackers to view and steal data and images. All data is stored in high resolution on the aircraft microSD card, and low-resolution data can be stored on the controller microSD card. The drone is also not subject to geo-fencing, so control remains in the hands of the pilot. In other words, SIRAS enables pilots to launch within a minute of powering up, no questions asked, and take responsibility for knowing when it is safe to fly.

Watch!

The SIRAS drone is also outfitted with a gimbaled dual-camera Vue TV128 payload, including a high-resolution radiometric thermal (FLIR Boson), a 640x512 infrared thermal camera with 5x digital zoom, and temperature-measuring capabilities. The payload also includes a visible 16MP camera with up to 128x zoom to pinpoint details, all attached to a swappable quick-connect system.

It is the only complete airframe solution with the patented FLIR MSX technology. It adds visible edges and outlines to thermal imagery to provide critical information in real-time and for post-flight analysis. Unlike image fusing (merging visible light imagery and thermal imagery), MSX is additive and does not dilute the thermal image. The affordable SIRAS is well suited for industrial inspections, law enforcement operations, firefighting, search, rescue, and mapping missions.

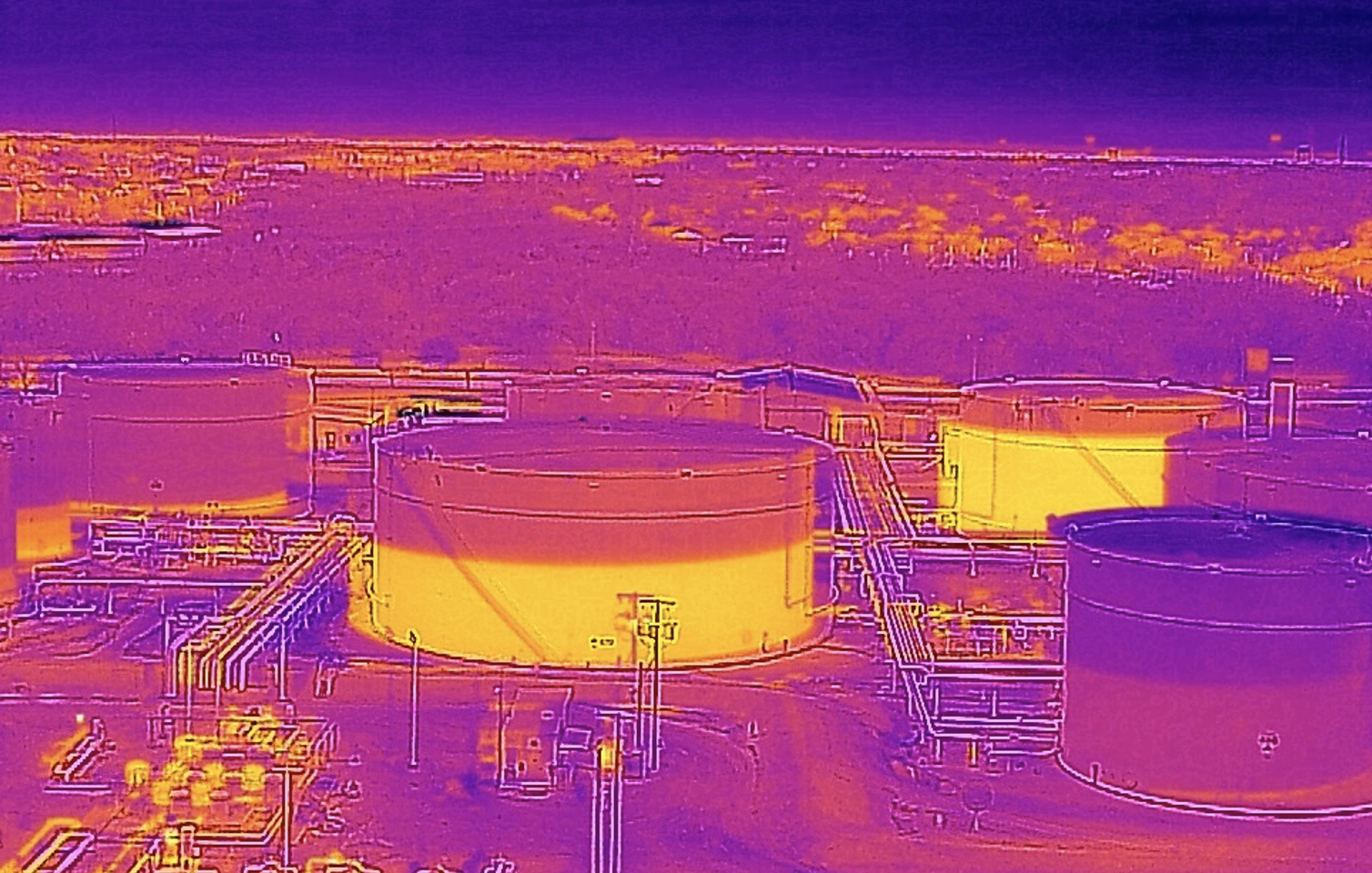

Thermal cameras see tank levels and FLIR MSX embosses visible light edges on a thermal image. [Photo credit: Lone Star Drones.]

Effective Data Interpretation and Reporting

With an effective drone and corresponding payloads, the next step is to capture the data required by leveraging the pilot’s skill, including flying in the right conditions and the right relationship to the target. Post-flight, processing images correctly and reporting those findings is vital—every step prior will not matter unless the data can be extracted and interpreted to accomplish the mission. FLIR Thermal Studio software is a powerful tool to optimize captured images and video: to make accurate measurements, batch process images, and report findings—all in a single program.

The before-mentioned SIRAS professional drone provides high-resolution radiometric thermal imagery for industrial and utilities inspection. Pilots can efficiently manage thousands of thermal images and videos with advanced processing features when used in concert with FLIR Thermal Studio Suite. Then they can use that information as part of predictive maintenance or condition monitoring programs of critical components. Pilots can also conduct system troubleshooting to complete missions faster and more accurately than ever before.

Imaging Optimization Through Thermal Tuning

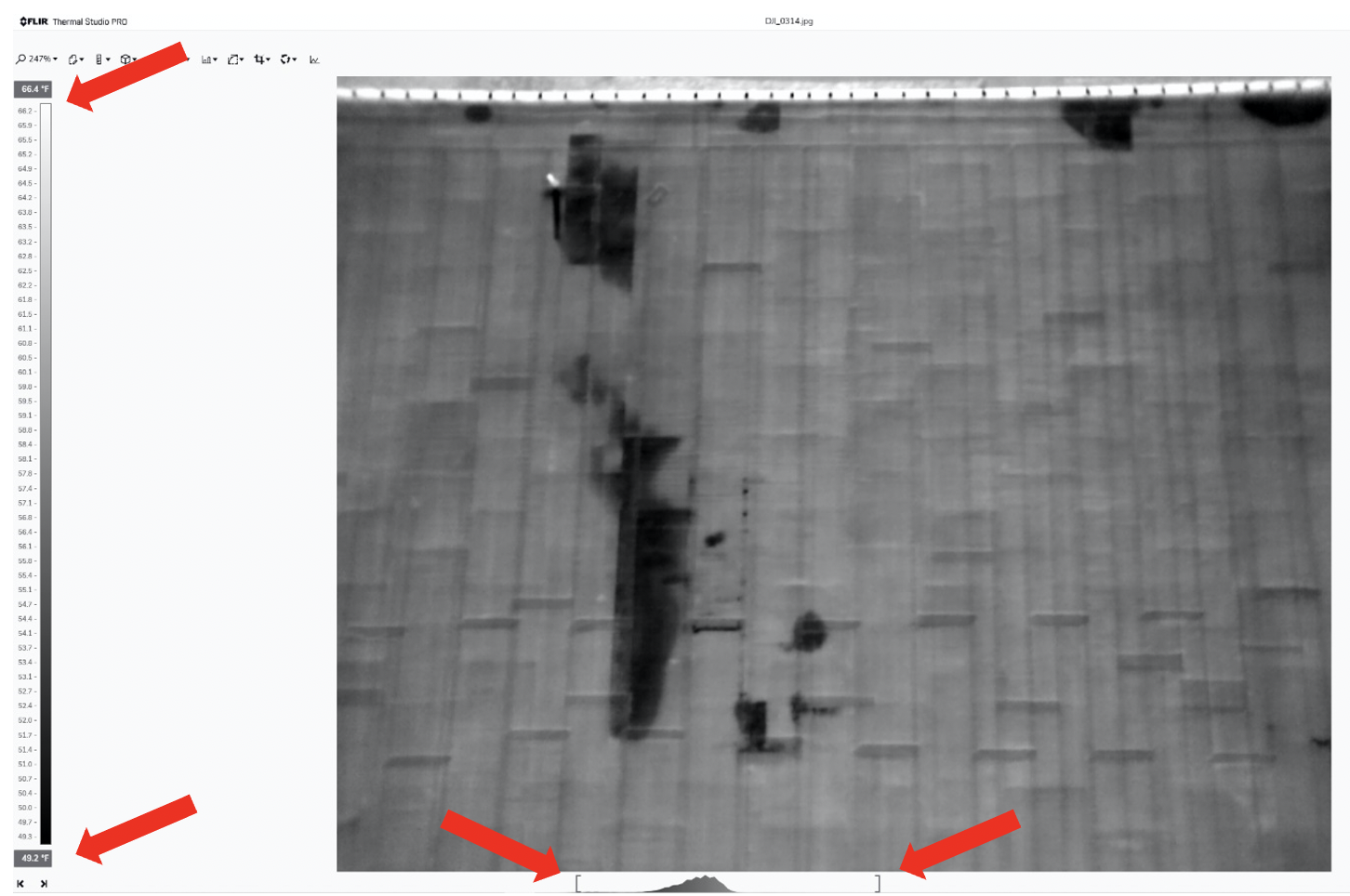

Sometimes, the raw imagery captured during a mission doesn’t offer the related details or interpretation needed. Here, the pilot can load the data into Thermal Studio Suite to adjust how the image appears to make the appropriate determinations. Adjusting the image, such as the image color palette, or focusing on a specific area of interest to gauge the captured temperatures of a group of pixels, might be required.

The operator may also need to adjust the image’s “span” manually, the window of temperatures the inspector is looking for in an image, and the “Level,” which is the mid-point of the span. Think of these definitions in terms of a television set, where span concerns contrast and level represents brightness. The operator can better examine temperature data within a specific range through this process, called thermal tuning. There might be hotter or colder temperatures measured in the scene, but if the operator is only concerned with measuring a specific temperate range, it makes identifying those temperatures significantly easier to save time and improve productivity.

Roof with adjusted span of 49.2°F -66.4°F enhances thermal anomalies that may denote an issue.

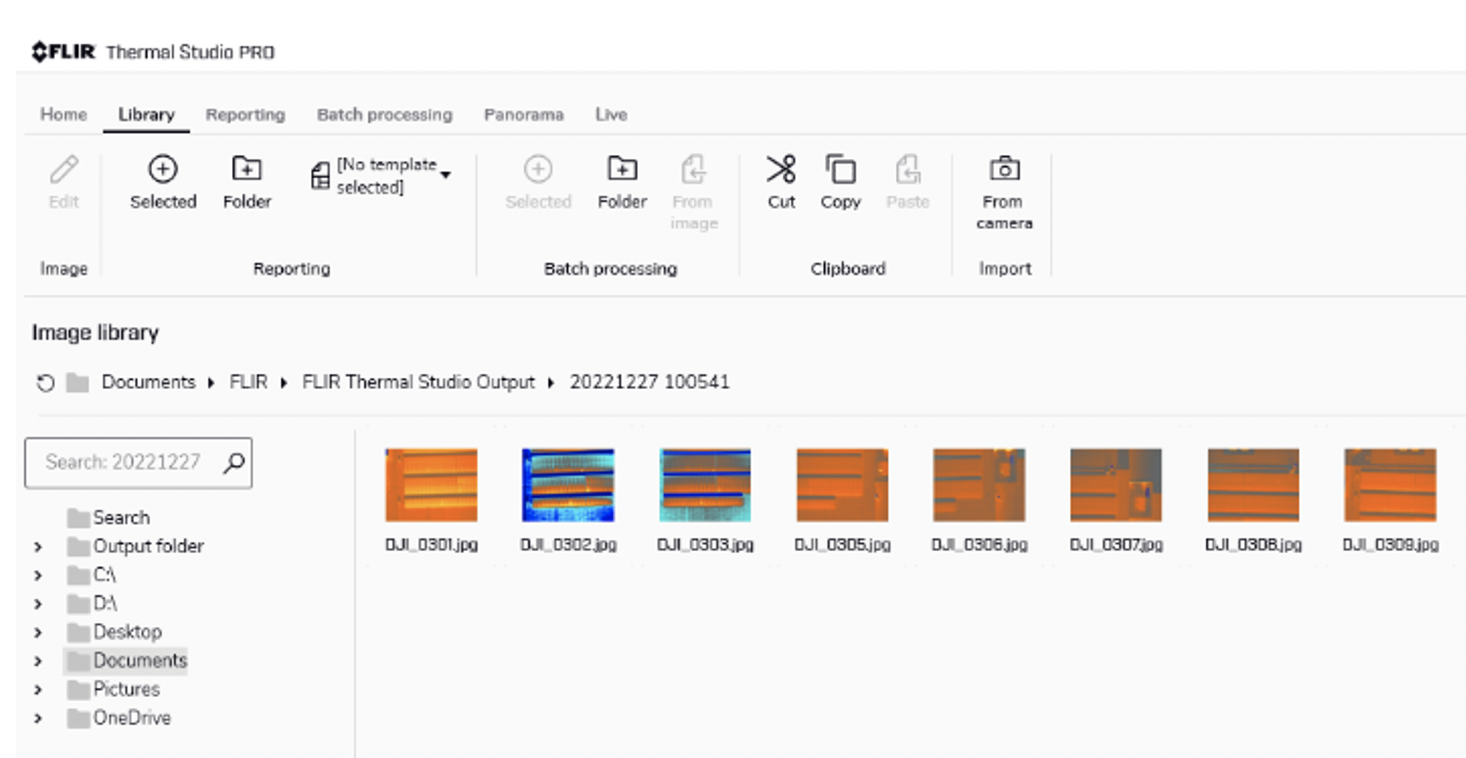

Batch Processing

One of the significant advantages of doing thermal inspections with drones instead of handheld cameras is the ability to inspect expansive areas quickly while capturing many images in the process. Plus, roof and solar inspections usually require capturing large datasets of images for creating orthomosaics and other collective data products. These datasets can be thousands of images.

Thermal Studio’s batch processing function is a tremendous time saver for drone pilots. Batch processing empowers the user to select multiple images to process, then apply the same color palette, temperature scale, temperature measurement parameters, and more to the entire dataset in seconds. This can save hours preparing images for reports and entire datasets for stitching.

Batch processing applies parameters and more to multiple images simultaneously.

Reporting the Data

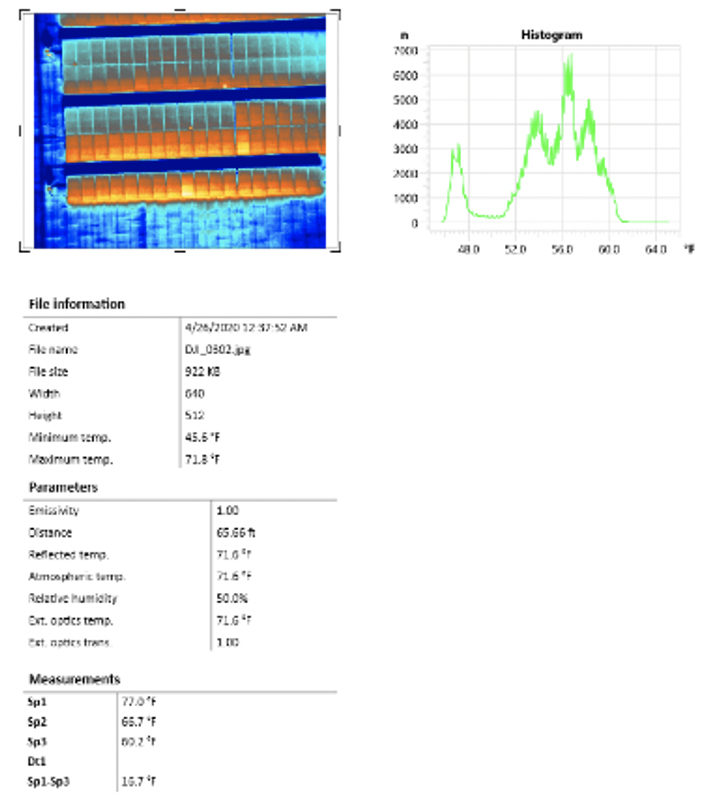

The final step represents compiling the processed images, videos, and data into a report that summarizes the key findings. Thermal Studio and other third-party software allow users to compile digital reports that can be shared with colleagues, customers, partners, and officials.

In Thermal Studio, once that analysis is complete, the software includes a button to add images to a report. Then, the user selects the appropriate report template, or they may create their own, and the system automatically generates the report. Thermal Studio reports also contain all the measurement data and notes fields for additional required commentary and recommendations. The report can be provided to anyone with Thermal Studio for editing and analysis, or it can be exported as a PDF for anyone to see.

One Solution, Start to Finish

The SIRAS professional drone and its dual-sensor payload provide critical information for industrial inspection, including for roofs, utilities, solar, and more. Paired with Teledyne FLIR’s Thermal Studio, drone operators have the tools they need to complete inspections and publish reports with all the required data to ensure a successful mission.

Share PDF reports to efficiently drive maintenance.